Tackling Asphalt Tack

Protecting your equipment and profits

The Silent Killer Crippling Asphalt Operations:

Are you ready for the cure?

The asphalt industry, the backbone of our infrastructure, faces a relentless and often underestimated adversary: Asphalt Tack

- silent killer of efficiency

- drain on profits

- constant source of frustration for plant owners and operators

While you focus on mix designs and project deadlines, asphalt tack is insidiously clinging to your equipment, grinding down your bottom line one sticky layer at a time.

Every day, tons of viscous asphalt course through your plant, over your conveyors, into your trucks, and on your paving equipment. And with every pass, a little bit stays behind.

It's the unseen tax on your operation, manifesting in a cascade of costly problems that you can no longer afford to ignore.

Are you aware of the true cost of this sticky reality?

Let's peel back the layers of this asphalt adhesion nightmare:

Slat Conveyor Catastrophes

Uneven Material Flow

Increased drag

Motor and bearing strain

Frequent cleaning

Costly repairs

Production disruptions

Imagine your material flow grinding to a halt, choked by stubborn buildup. Uneven material feed leads to inconsistent mixes and wasted material.

The increased drag puts undue strain on motors and bearings, leading to premature failures and costly emergency repairs.

Plus the endless cycle of scraping and cleaning disrupts production schedules, turning potentially profitable hours into periods of frustrating downtime.

Truck Bed Binding

Slowed unloading times

Reduced loads per shift

Increased labor costs

Difficult cleaning

Truck bed lining damage

Picture your trucks struggling to unload, valuable time wasted as drivers wrestle with sticky beds. Reduced loads per shift directly impact your delivery capacity and profitability.

The increased labor required for manual cleaning, often with harsh and potentially damaging methods, adds another layer of expense.

And the wear and tear on truck bed linings from constant scraping is a hidden cost that eats away at your margins.

Double Drum Roller Distress

Reduced compaction effectiveness

Uneven surfaces

Roller surface damage

Costly resurfacing or replacement

The very machines designed to create smooth, compacted surfaces are themselves becoming victims.

Asphalt caking onto the drums reduces compaction effectiveness, leading to uneven surfaces and the risk of rework.

The constant battle to keep rollers clean can damage their surfaces, causing expensive resurfacing or even complete replacement.

It isn't just about aesthetics; it's about the quality of your work and the longevity of your investment.

Increased Maintenance and Downtime

Lost production

Higher labor costs

Impact on bottom line

The cumulative effect of these individual issues is a dramatic increase in maintenance frequency and prolonged periods of unproductive downtime.

Lost production translates directly to lost revenue, and the higher labor costs associated with constant cleaning and repairs further erode your profitability.

This isn't just inconvenient; it's a significant drain on your resources.

Reduced Equipment Lifespan

Accelerated wear and tear

Frequent maintenance and parts

Premature costly replacement

Lost production awaiting replacement

Impacts bottom line

The constant struggle against asphalt tack accelerates wear and tear on all your critical equipment.

Motors work harder, bearings fail sooner, and surfaces degrade faster.

Premature aging forces you into costly replacements far sooner than necessary, a silent killer of your long-term capital investments.

Fundamentally change this sticky reality

Proactively shield your assets and reclaim lost profits

Introducing TecShield

NTPEP Tested and Certified

The TecShield difference is a unique formulation creating a bond-breaking layer that withstands the high heat and pressure. This insures consistent release where it matters for achieving optimal compaction and surface quality.

TecShield is not just a product: it is a strategic investment in the longevity and profitability of your entire operation. Other companies can offer Asphalt Release Agents, however they cannot offer the performance of TecShield.

No other product on the market comes close to addressing the asphalt adhesion on double drum rollers.

Features:

Advanced Release Technology

Durable, non-stick barrier

Prevents Asphalt adhesion

Clean and efficient material handling

Enhanced Equipment Protection

Reduced Wear and Tear

Extended equipment lifespan

Minimized maintenance costs

Improved Efficiency

Faster material flow

Reduced downtime

Increased production output

Environmentally Friendly

Minimizes harsh solvent impact

Reduces environmental impact

Safe for human contact

Ease of Application

Easy to apply via spray or wipe

Consistent and effective coating

Cost Effective

Reduces maintenance

Extends equipment life

Significant return on investment

.

Isn't it time you shield your profits?

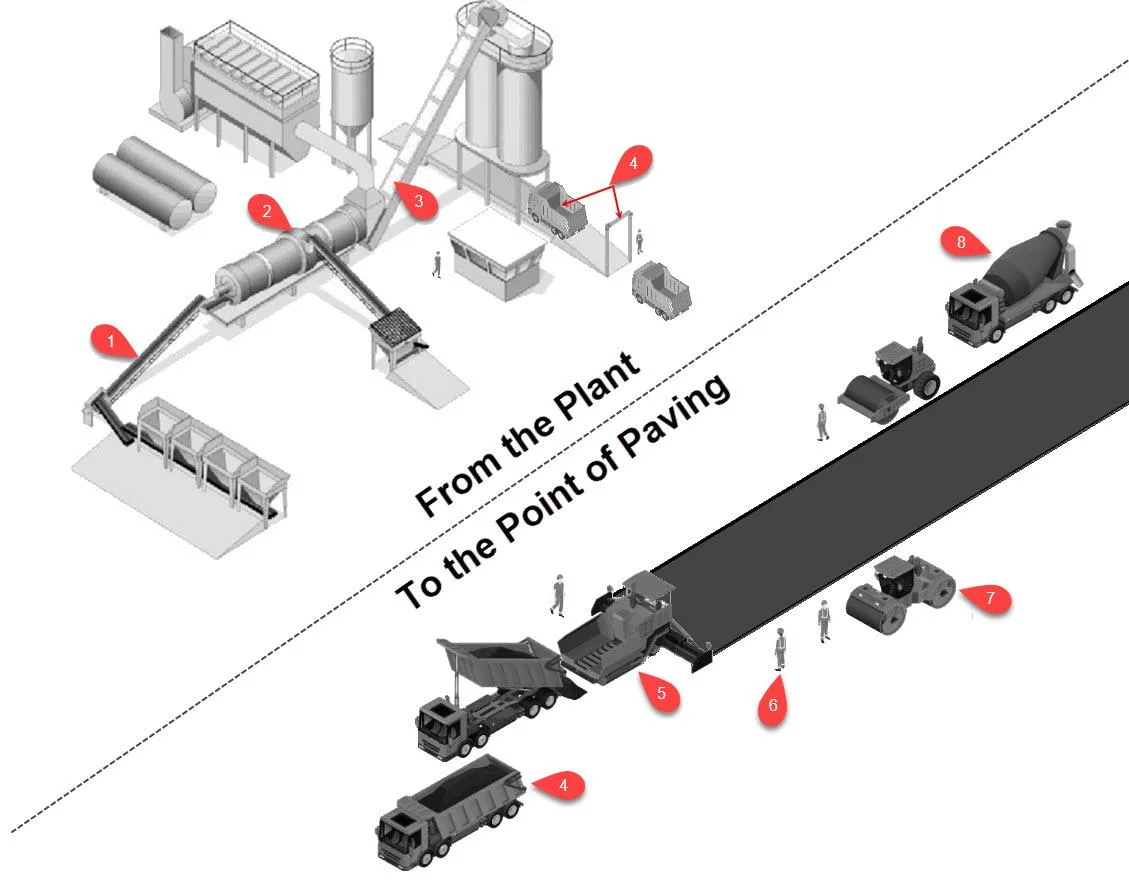

Use TecShield On:

Raw Material Conveyors - operates with less effort. Material flows smoothly. Will lengthen life of parts. Protects conveyor belts and components. Improves fuel efficiency by reducing drag.

Double Drum Rollers - maintain peak performance. TecShield forms an impenetrable shield insuring consistent compaction, eliminating uneven surfaces and protecting the surfaces of your roller from damage.

Drag Slat Conveyors - operates with less effort. Material flows smoothly eliminating uneven feed, reducing drag, and drastically reducing motor and bearing strain.

Truck Beds - prevent asphalt from sticking to truck bed in the first place. Increase loads per shift and reduce labor costs. Use with Automated Spray Systems.

Pavers - prevents buildup in the Hopper, on Augers, and Screed while it ensures consistent mat quality,

reduces cleaning and downtimeHand Tools - prevents asphalt sticking and reduces cleaning time and effort. Improves worker efficiency and reduces fatigue

Compaction Vehicles (Rollers) - eliminates asphalt pickup on drums and tires which maintains consistent compaction. Extends roller lifespan.

Concrete Vehicles as well.

Material Transfer Vehicles ( not shown) - prevents buildup in the Hopper and on Conveyors, and reduces cleaning efforts and downtime. Protects conveyor belts and components. Improves fuel efficiency by reducing drag.

From the Plant to the Point of Paving

Get TecShield Today

We are ready to help

Profits in Pockets, Not in Parts

FOLLOW US

BUSINESS

INDUSTRIES

PARTNERSHIPS

LEGAL

PRODUCT SDS

PRIVACY POLICY

© 2024 TecTeam LLC. All rights reserved.